Greene Fire is proud to announce that our next-generation MK2.1 FireMaster FZ Bushfire Shutter has officially achieved BAL–FZ certification under AS 1530.8.2 – Simulated Bushfire Attack conditions, following rigorous testing at CSIRO’s North Ryde Fire Testing Laboratories. This certification, confirmed in CSIRO Report FCO-3559 dated 31/08/2025, represents the highest bushfire risk level and validates the shutter’s ability to withstand direct flame contact, extreme heat radiation, burning debris, and ember attack for 30 minutes, followed by a 60-minute observation period.

Engineered for Australia’s most extreme fire zones, the MK2.1 FireMaster FZ incorporates our newly developed EFP BF Bushfire Fabric, delivering unmatched heat resistance and durability. The product is now in full production and available with internal or external 230v motors (remote or wireless control).

This milestone reflects Greene Fire’s commitment to pushing beyond compliance and setting new benchmarks for bushfire protection, safety, and innovation.

Why BAL–FZ Matters

BAL (Bushfire Attack Level) ratings define construction requirements in bushfire-prone areas. BAL–FZ represents the most severe risk category, requiring solutions capable of withstanding direct flame and extreme heat. Certified products like the FireMaster FZ Shutter are critical for safeguarding properties on the bushfire frontline.

Thank You to CSIRO

We extend our sincere thanks to the team at CSIRO Fire Testing Labs – Peter Gordon, Glenn Williams, and Juan Baena Vargas – for their expertise and collaboration throughout this process.

Greene Fire recently undertook rigorous testing of our Next Generation MK2.1 FireMaster FZ Bushfire Shutter at CSIRO’s North Ryde Fire Testing Laboratories under AS 1530.8.2 - BAL-FZ Simulated Bushfire Attack conditions. This demanding standard replicates the most extreme bushfire conditions, classified as BAL-FZ (Flame Zone) the highest possible risk level, where buildings are directly exposed to intense heat and flame from a potential fire front for 30 minutes, followed by a detailed 60 minute observation period.

The results provided the next step in engineering required to evolve our MK2.1 FireMaster FZ product to meet and far exceed the BAL-FZ threshold.

Every test, every prototype, and every refinement moves us closer to delivering updated market-leading bushfire protection. Our continued partnership with CSIRO and our investment in proprietary materials, such as the newly developed EFP BF shutter fabric, demonstrate our unwavering commitment to product performance and compliance in Australia's most demanding environments.

We are now further advancing the MK2.1 FireMaster FZ Shutter, taking the data from this test and using it to optimise the system’s resilience in real flame-zone conditions.

What does this mean for the FireMaster FZ Bushfire Shutter Certification?

- Further update to recent AS1530.8.2 testing with CSIRO Infrastructure Technologies Sydney NSW: The Greene Fire BAL-FZ Bushfire Shutter MK2.1 technical updates have now been approved for assessment to BAL-FZ rating.

- Pre-production has now commenced utilising the newly developed EFP BF Bushfire Fabric as the basis for all Greene Fire BAL-FZ Bushfire Shutters, providing unmatched technical performance to the BAL-FZ product range

- Greene Fire BAL FZ Bushfire Shutter MK2.1 is now available with both internal or external 230v motors w/remote control or wireless operation, as well as our external gear drive or pulley type manual operators.

Why BAL-FZ Matters

As rebuilding continues across bushfire-prone areas, BAL (Bushfire Attack Level) ratings determine the construction requirements for safety and compliance. BAL–FZ represents extreme risk, and solutions certified to this standard are critical for safeguarding properties on the bushfire frontline.

This test is a vital step in Greene Fire’s broader mission: to push past compliance and create bushfire protection systems that set new benchmarks for performance, safety, and innovation.

Thank You to CSIRO

We extend our thanks to the team at CSIRO Fire Testing Labs - Peter Gordon, Glenn Williams and Juan Baena Vargas - for their continued collaboration and expertise.

Greene Fire is proud to share the results of a successful two-day testing program with Resolute Testing Laboratories in Lawnton, QLD, where we conducted AS 1530.7-2007 smoke control testing on two of our core products - the Aluflam AF70 Door and the FireMaster Fire Curtain.

These rigorous ambient and medium temperature air-leakage tests are part of the broader industry shift toward performance-based solutions for smoke control, providing quantifiable data that demonstrates a product’s effectiveness in limiting the spread of smoke through protected openings. The testing was carried out in accordance with AS 1530.7, which assesses smoke leakage under controlled pressure and temperature conditions, using air as a proxy for real smoke to simulate the dynamics of smoke migration during a fire event.

We’re pleased to report that both the FireMaster Fire Curtain - constructed with our standard EFP A1 fabric for up to (240mins.) of fire resistance - and the Aluflam AF70 Door (60min.) - fitted with standard hardware, 14mm Contraflam Lite FR glass, and profile-filled frame - delivered excellent results.

Each assembly successfully met the stringent air and smoke permeability thresholds set out in the standard, confirming compliance with AS 1530.7 and offering robust assurance of performance for both ambient and elevated temperature conditions.

This test also reinforces Greene Fire’s commitment to innovation in smoke and fire protection, with products that not only meet but exceed current building code requirements.

Our fire doors and curtains are not just passive elements in a fire strategy - they’re engineered solutions that respond to real-world challenges, allowing architects and specifiers to choose systems with validated, measurable smoke control capability.

We extend our thanks to the team at Resolute Testing Laboratories for hosting us and facilitating another professional and informative testing process.

At Greene Fire, we’re not just fire-rated - we’re performance-proven.

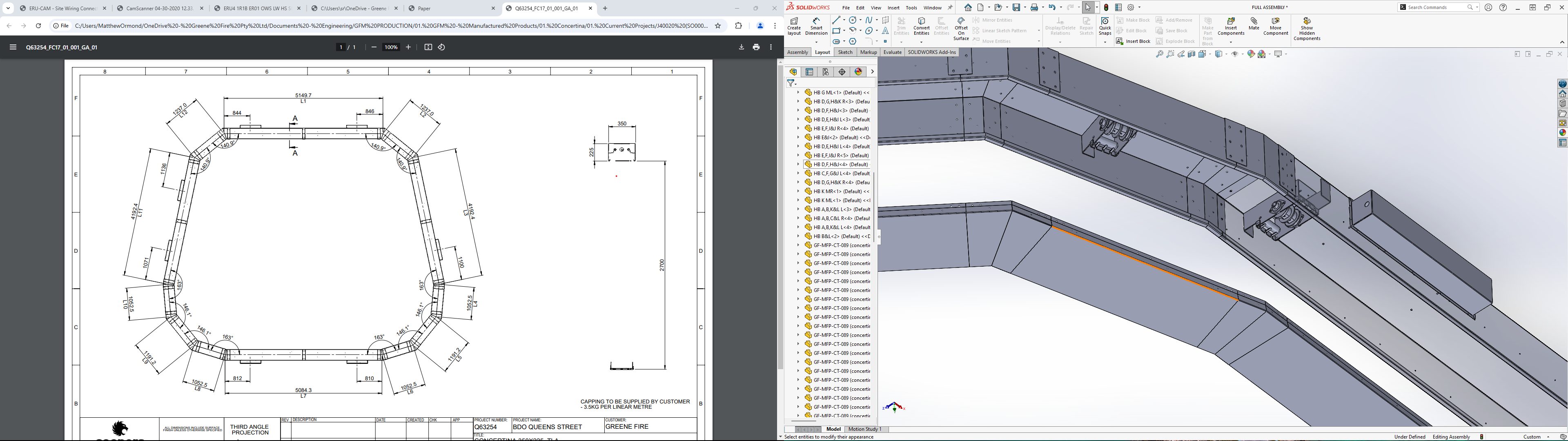

Greene Fire recognised that design in the manufacturing industry is evolving rapidly, with increasing demands for precision, speed, and sustainability. Meeting these challenges requires advanced tools capable of streamlining design processes while maintaining rigorous safety and regulatory standards.

Greene Fire faced these industry-wide challenges head-on by integrating SOLIDWORKS into its operations. The platform has provided a comprehensive solution to accelerate project timelines, improve design accuracy, and deliver unparalleled safety and performance in its products.

Leveraging SOLIDWORKS for Superior Results

Greene Fire’s integration of SOLIDWORKS into its design and manufacturing operations has been transformative, enabling the company to achieve remarkable improvements in efficiency, collaboration, and sustainability. The software has become a cornerstone of Greene Fire’s commitment to delivering innovative, high-quality fire protection solutions tailored to the unique requirements of its clients.One of the most significant benefits of adopting SOLIDWORKS is the drastic reduction in design timelines. Previously, developing complex fire protection systems, particularly those customised for unique architectural needs, could take several weeks. These designs often relied on collaboration with experts from multiple countries, adding complexity to the process. With SOLIDWORKS, Greene Fire has successfully cut its design cycles by 50%. This acceleration allows the team to finalise intricate projects in a fraction of the time, meeting tight deadlines and responding to client demands almost immediately.

In addition to improving speed, SOLIDWORKS has revolutionised how different departments within Greene Fire collaborate. The software’s seamless integration ensures that every stage of a project, from initial design and 3D modelling to manufacturing - is aligned. This integration eliminates common communication bottlenecks that can arise when transitioning between departments, creating a streamlined workflow that fosters teamwork. Design teams, project managers, and engineers can now work in unison, reducing errors and ensuring that projects are delivered on time and within budget. This cohesive approach not only improves operational efficiency but also enhances the overall quality and reliability of the final product.

With sustainability being a core value at Greene Fire, SOLIDWORKS plays a pivotal role in supporting the company’s environmental goals. The software’s advanced tools for material optimisation enable the team to reduce waste without compromising product integrity. By carefully analysing material requirements and minimising excess, Greene Fire ensures that its operations align with sustainable practices.

Another standout feature of SOLIDWORKS is its capability to reuse and adapt previous designs for new projects. This functionality significantly reduces the time and resources required for product development. Rather than starting from scratch, Greene Fire can leverage proven designs, customising them to meet specific client requirements. This method ensures consistency and reliability while accelerating innovation. The ability to build upon a strong foundation of past work allows the team to focus on refining and enhancing their solutions, driving continuous improvement across all projects.

Overall, SOLIDWORKS has been instrumental in Greene Fire’s ability to maintain its leadership in the fire protection industry. By enabling faster design cycles, fostering seamless collaboration, optimising material usage, and accelerating innovation, the software has empowered the company to deliver superior results while staying true to its values of quality, sustainability, and customer satisfaction.

A Testament to Innovation and Excellence

Clinton Greene, the founder of Greene Fire, underscores the transformative impact of SOLIDWORKS: “Our adoption of SOLIDWORKS has fundamentally changed how we approach design and manufacturing. The platform empowers our team to explore innovative ideas and deliver high-quality solutions that meet the demands of modern construction”.The Research and Development (R&D) team at Greene Fire has particularly benefited from SOLIDWORKS’ capabilities. The ability to conduct comprehensive designs has accelerated the team’s ability to innovate. Greene Fire’s R&D efforts are now leading the industry in developing compliant solutions.

With SOLIDWORKS at the core of its operations, Greene Fire is well-positioned to lead the fire protection industry into the future. By embracing cutting-edge technology, Greene Fire not only meets the demands of today’s construction challenges but also anticipates the needs of tomorrow.

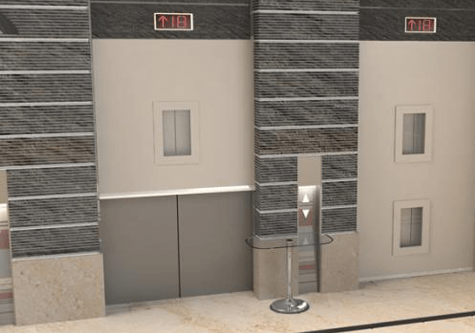

The perfect solution for unsprinklered buildings, the FireMaster Insul8 provides dry insulation. The curtain deploys automatically from a fire alarm signal, forming a fire-resistant and insulated barrier that contains flames and gases, thereby protecting life and property. Its ability to provide 90 minutes of insulation (below 140°C) ensure protected evacuation for occupants to safe areas while enabling safer firefighting operations. The FireMaster Insul8 is ideal for lobbies and receptions, lifts and egresses, evacuation routes and boundaries.

The curtain complies with the highest industry standards, having been tested to the rigorous requirements of BS EN 1634-1:2014 by an accredited testing laboratory. For more information on FireMaster Insul8, its applications, and key benefits, visit the product page or contact Greene Fire.

Learn More

If you wish to obtain information regarding our fire engineered solutions please click on the products page for more information. Alternatively you can contact us directly at (02) 9526 3100, or email us at sales@greenefire.com.au.

“Looking to local manufacture is an obvious step to be able to meet our customer’s needs. The construction industry struggles with long lead times and non-standard items, so as our products become in more demand, we need to invest in delivering faster. We have done the same with our fire curtains, so we have experience in doing this.” said Clinton Greene, Greene Fire’s Director.The unique and patented design of the Aluflam system provides the building industry in Australia with fire rated systems made from thermally broken aluminium joinery, something that is normally expected to be made in steel or timber. Windows, doors, partitions, facades, floors and skylights can be manufactured with fire ratings up to FRL -/120/120.

Aluflam produces high end fire rated products, and supplies all over the world, both onshore and offshore. It was therefore important to us that we have the right partners. We have had a fantastic collaboration with Greene Fire over the last 5 years and when we decided to start production locally in Australia, it was natural to enter into a partnership with Greene Fire. Greene Fire fully meets the same high standards of quality control, customer satisfaction and has been able to adapt our products to the Australian market.” says Peter Birck, CEO and Founder of Aluflam Group.The Aluflam products have been designed to the highest specification for commercial buildings. There is no compromise to the architect’s design. These beautiful windows and doors have been used in residential and domestic housing with new products coming soon, specifically for the Australian bushfire market. More information can be found at www.aluflam.com.au or on LinkedIn www.linkedin.com/company/aluflam-australia About Greene Fire: Greene Fire is a family owned and operated business established in Australia in 2000. We pioneered fire and smoke curtains within Australia and more recently our capability in delivering engineered solutions has expanded to offer fire shutters, fire rated glazing, bushfire solutions, MicroLouvre, glazed louvres, along with several non-fire rated solutions. About Aluflam: Aluflam is a family-owned business that was established in Denmark in 1943 with more than 25 years of experience in fire-rated glass and aluminium construction. We offer a wide selection of fire-rated constructions, from fire-resistance classes E15 to EI120 such as facades, windows, doors, sliding doors, skylights and glass roofs. Our designs range from standard to more complex, specially designed systems. Introducing Aluflam Australia.

Learn More

If you wish to obtain information regarding our fire engineered solutions please click on the products page for more information. Alternatively you can contact us directly at (02) 9526 3100, or email us at sales@greenefire.com.au.

Introducing the ResQ window.

This ‘window’ is a patented translucent fire proof flexible material which was created to address this issue. The ResQ-Window™ can be installed into a fire curtain allowing building occupants and first respondents to see through the curtain after it has been deployed. This allows for building occupants to be aware of where the fire is located allowing them to escape in a safe manner. It also allows first respondents to easily locate the source of the flame and eliminate the danger in a more effective process.The curtain with a vision panel is designed for:

- Escape

- Lift openings and lobbies

- Areas where Fire Marshals and the Fire and Rescue Service may need to assess prior to entry

benefits

- See through a deployed curtain as a means of escape

- Safely egress from lifts

- Suitable for lift lobby muster points

- First respondent can clear a building faster

- First respondent can see the presence of an occupant on the other side of a curtain

- First respondent can see the presence of fire on the other side of a curtain

- First respondent can see the presence of smoke on the other side of a curtain

How can this issue be resolved?

Fire Curtains and smoke curtains are solutions which can be used as they are able to compartmentalize a room, corridor or space and offer reliable boundary protection. This has allowed designers to replace non-loadbearing fire walls and doors, fire doors, fire rated glazing, and sprinklers to achieve modern and safe open plan environments. Fire curtains and smoke curtains are, as their names suggest, curtains that prevent the damage and threat from heat and smoke in the event of a fire. The role of a fire curtain is to segregate a fire in a building or large room, allowing successful evacuation of the space. This makes them an ideal solution for public properties that feature large, open rooms. The curtain is hidden within a small headbox which can be designed into a structure and hidden from view. Alternatively it can be retrofit into a building either face fixed to a structure or hidden in the current structure (assuming space is available). The curtain will remain retracted within its head box until it is automatically activated by the fire alarm signal. Once activated it will completely close the opening, creating a fire and smoke compartment. Deployment is by gravity at a controlled speed of 0.06 – 0.15m/s. In the case of a power failure the curtain will automatically deploy, ensuring that compartmentation will be guaranteed in any scenario.Forms of Fire curtain systems.

Tadalafil contraindications include nitrate therapy and cardiovascular conditions; Consult https://www.edshine.com.au/cialis-tadalafil/ for detailed interactions.

Our ViiFire range of products are compact fire curtains which can be provided as insulated or non-insulated solutions. These systems come as plug and play systems which can be easily retro fit to any structure. These solutions are primarily used in boundary protection, fire separation for elevators, and many more. An example of our ViiFire system would be our ‘Juntion 24, Victoria’ Project. This project required boundary protection due to its close proximity to the property boundary. ViiFire systems were used on all external openings, satisfying the requirement for a -/60/- fire rating. To learn more about how our solutions can be your solution to having a wide open space, visit our product pages for more in depth information on our range of fire and smoke curtains. Alternatively you can read our white paper ‘optimizing passive design‘ for another look at how passive design is the future of design.

What is BIM?

BIM (Building Information Modeling) is a process which is highly collaborative allowing multiple parties to coordinate the planning, design and construction of a building. This form of collaboration is most commonly used in Architecture, Engineering and Construction. BIM utilizes realistic 3D objects to create high quality 3D models which can be viewed by all stakeholders. There are many misconceptions surrounding BIM modeling. Many believe that this system is only used by architects in the design of a building, this however is not the case. BIM software has gone beyond traditional 3D CAD modeling. BIM models utilize objects which are intelligent, have geometry and store data. If any object is changed, the BIM software updates the model illustrating the changes and providing data on how the change impacts the project. This software develops a model which remains consistent throughout the development of a building and creates a collaborative environment in which architects, engineers, designers, project managers, etc. can work in conjunction with one another. This information is shared through a mutually accessible online portal known as a common data environment, with the collected information being referred to as information models. These information models can be used at any stage of a building’s lifecycle, including future renovations.What are the BIM levels

As defined by Trimble Building, there are multiple BIM levels in which you can incorporate this modeling software into the development of your building. These levels range from level 0 to level 3 with future growth up to level 6D. These levels are differentiated based on how effectively the information of a project is being shared throughout the entire process.Level 0

Level 0 BIM refers to a complete lack of collaboration. This level includes the use of 2D CAD and working with drawings/digital prints. Most developments have exceeded this level, however there are some instances in which these systems are still in use.Level 1

Level 1 involves the use of 3D CAD for concept work, however, utilizes 2D for drafting production information and other documentation. This level incorporates data sharing via a common data environment which is usually managed by the contractor. Many firms are at a Level 1 BIM, which doesn’t involve great collaboration with each stakeholder publishing and managing their own data.Level 2 BIM

Level 2 BIM begins to develop a collaborative environment. This level involves all stakeholders utilizing 3D CAD models however sometimes not the same model. Collaboration is further enhanced by sharing data through a common file format, for example Industry Foundation Class (IFC).Level 3 BIM

This level is currently the most collaborative form of modeling in building development. This level utilizes a singular shared model which is used by all stakeholders allowing for greater communication between parties and reducing faults and miscommunications.What are the Key Benefits of BIM modeling?

Prior to the introduction of BIM many projects were seeing negative results due to poor communication and inefficient construction. This led to roughly 80% of projects going over budget and jobs taking an average of 20% longer than scheduled. BIM modeling allows for a collaborative environment in which all stakeholders are involved in 100% of the development of a structure. This allows for greater information sharing and the removal of miscommunications. By working on 1 shared model, separate stakeholders can create designs which incorporates the requirements of various components. This lowers human error significantly and ensure that specific components of a development are done on time and in the correct way. Through greater awareness of what is required to perform all components of construction, costs can also be more effectively managed.We support BIM modeling!

To ensure we are up to date with current technology trends, our partners at coopers fire have developed BIM files for our key fire curtain products. To download these files, please visit the desired product page. As our products allow for greater design freedom and larger more spacious areas, you will be able to create design models which incorporates our solution into your design. This will provide you with greater details on the freedom of design which you have allowing you to create spaces without being restricted. For further reading on the subject, visit the page below. S, Lorek.(2018). What Is BIM (Building Information Modeling). https://constructible.trimble.com/construction-industry/what-is-bim-building-information-modeling. 29/05/2019.

WHAT IS A CLEANROOM?

Typically used in manufacturing or scientific research, a cleanroom is a controlled environment that has a low level of pollutants such as dust, airborne microbes, aerosol particles, and chemical vapors. This is usually specified by the number of particles per cubic metre at a specified particle size. For use in cleanrooms all materials must be non-shedding and non-absorbent. Ledges, cracks, crevices and inaccessible places which gather dust and are difficult to clean must be minimised as far as practical. All exposed surfaces must be compatible with and easily cleaned with common cleaning and disinfectant chemicals routinely used in hospitals and biological research facilities. A classic use of cleanrooms has been in scientific laboratories and research facilities. However, these Cleanrooms are becoming more and more prevalent as technology grows. A common use of cleanrooms is in the development of our mobile devices such as phones, laptops, camera’s, etc. These devices utilise small components such as microchips and lenses. As these components are so small and require such intricate and precise development, a small speck of dust could render a microchip ineffective. A cleanroom would be required in order to ensure that the component is developed correctly without any damage.APPLICATIONS OF THE FIREMASTER CLEANROOM

The FireMaster Cleanroom is a fire curtain which can be used to replace non-load baring walls, doors, and windows creating a vast open space whilst maintaining compartmentation. As the curtain has achieved 2 hours of heat insulation, this product is also used to protect escape paths allowing time for individuals to escape. They can also offer property, equipment and external boundary protection.HOW DOES IT WORK?

The FireMaster Cleanroom is manufactured from 316L grade stainless steel suitable for use in a cleanroom environment. The FireMaster Cleanroom features a stainless-steel curtain that does not release particles in operation and features side guides that can be manually opened and closed for cleaning. The curtain remains hidden within its headbox until deployment. Once deployed the curtain lowers via gravity at a controlled pace of 0.06 – 0.15m/s until it completely seals the opening. Once sealed the curtain prevents fire spread throughout a building, and between buildings. The headbox and side-guides have been specifically designed in order to allow easy access for cleaning and maintenance.TESTING AND CERTIFICATION

The FireMaster Cleanroom has been fire tested as part of Exova Warrington’s CERTIFIRE scheme. Additional tests for cleanroom suitability were also carried out in Germany at the Fraunhofer Institute for Manufacturing Engineering and Automation. The Fraunhofer TESTED DEVICE® is an internationally renowned certification mark for products that have been objectively qualified in accordance with recognised standards and guidelines with regard to their cleanroom. The FireMaster Cleanroom is certified as suitable for use in cleanrooms fulfilling the specifications of Air Cleanliness Class 6 according to ISO 14644-1. It has a Class C rating under the pharmaceutical industry’s Good Manufacturing Practice (GMP) standards; and is rated at 1,000 under US Federal standard 209E. The chemical resistance of the curtain and headbox and side guides is tested according to ISO 4628-1. It is fire tested to BS EN 13501-2:2007+A1:2009 to provide an Integrity rating of E120 and EW120 for radiation.Learn More

To learn more about this solution, visit out FireMaster Cleanroom Product page. Alternatively you can give us a call at (02) 9526 3100, or send us an email at .

how does temperature affect productivity?

One of the leading factors impacting productivity is not what you would expect. Temperature has been found to drastically impact productivity levels. A study performed in 2002 measured the productivity of a call center and found that work speed reduced by 15% when the temperature raised from 24.8° C to 26° C.how does light affect productivity?

Lighting in the workplace has been discovered to significantly alter the work rate and productivity of workers. Apart from its physical effect on workers, there are also psychological effects that can affect the productivity of a worker. Mirjam Munch (2011) conducted a study testing the impacts artificial lighting has on productivity levels as opposed to natural lighting. It was found that subjects who were exposed to artificial light were significantly less productive and were found to be less capable of performing cognitive tasks (problem solving). They were also found to have higher levels of sleepiness as the day progressed causing a loss of attention. Not only is there an impact at the office but there is a strong relationship between workplace daylight exposure and office workers’ circadian rhythms impacting their sleep, activity and quality of life.

what are circadian rhythms?

Circadian rhythms are the biological, mental and behavioural rhythms that follow a 24-hour cycle (your body clock). They are produced by various factors, most notably light. Light is used as an ‘on’ or ‘off’ switch dictating your sleep cycle, hormone release, attentiveness and cognitive functioning. Disruptions of circadian rhythms is directly linked to sleep disorders, obesity, diabetes and depression.how do we maximize our productivity?

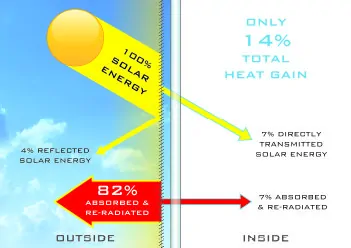

Given what has been mentioned, in order to maximize productivity, you need to have a strong source of natural lighting and you need to have a comfortable temperature in the office. But how is this achieved? Letting in too much natural light can make the office hotter and less productive, letting in no natural light will impact workers mentally becoming negative and less productive. Unfortunately air-conditioning cannot provide the answer to this.then what is the answer?

MicroLouvre Solar Shading Screens shade 100% of all direct sun when it is at its hottest stopping the heat before it reaches the window. This screen provides 80% open area ensuring that a comfortable amount of natural light passes through whilst blocking 92% of the heat. This maintains temperatures at a desired level whilst also eliminating glare and saving energy. MicroLouvre fabric is made from miniature woven bronze louvres, only two times thicker than a human hair, angled for optimum sun control, glare and light. It is easily and inconspicuously installed externally on buildings, in lighting units, display cabinets and many other applications. This system allows you to maximise natural lighting, and maintain temperatures, ensuring that the happiness and

SMOKE BAFFLES OR SMOKE CONTAINMENT

A number of key solutions are used within building design to combat the problems associated smoke zones and compartmentation prescribed by the BCA. These can include smoke baffles and/or smoke containment systems, however there are subtle differences between the two systems with varying products available on the market.Smoke Baffles

Smoke Baffles are non-combustible products (such as glass, plasterboard bulkheads or smoke curtains) that create a smoke reservoir with an intention to keep the smoke layer above head height to aid safe, unobtrusive evacuation. The advantage of using Smoke curtains is the flexibility. With a smoke curtain there are two options: i) a fixed smoke curtain baffle (mostly seen in industrial buildings) which is light weight and less prone to damage than glass or ii) a hidden, automatic drop-down smoke baffle which, when not in alarm, is completely invisible. This is very suitable to residential and commercial projects. Smoke curtains, used as automatic drop-down baffles are usually installed at high level and drop down to a pre-determined height to channel heat and smoke via extraction fans to specific extraction points, as part of a smoke control system. Often, side guides are not required so long as the fire engineer has taken into consideration any possible smoke leakage at the sides (and/or headbox) and is aware of any high pressures across the curtain causing the fabric to deflect.

Smoke Containment Curtains

Smoke containment curtains generally have side guides to create an efficient smoke seal. If the smoke curtain is not within an exit route then a typical full height drop down smoke curtain can be installed. Lift shafts and lobbies are a very typical area within a building that will require a sealed unit using guides that may even contain smoke seals within them. Many buildings may also require dual purpose compartmentation with egress. Modern smoke curtains now contain options for soft surface egress doors, eliminating the need for separate exit doors. During a fire event, occupants may pass through the curtain to the shortest path to safety, with the curtain closing safely behind them. However, a critical element to consider in the design of such a system is air or smoke permeability and smoke leakage.SMOKE LEAKAGE

As there is no specific Australian design guidance for Smoke Curtains, designers should consult the European Standard EN12101-1:2005 – Smoke and heat control systems – Part 1: Specification for smoke barriers. This standard provides everything from performance requirements to evaluation of conformity and is a required starting point for all designers using smoke curtains. EN12101-1 also specifies the maximum acceptable amount of smoke leakage at the edge of a smoke curtain to ensure that any opening allows only minimal amounts of smoke to pass through. Whilst the designer can specify to minimise gaps down to 0mm, maximum permissible gaps between a wall and smoke curtains are based on the height of the curtain and can be as follows:

Our top 6 benefits of using aluminium framing

1. Thermal performance

Many fire resistant windows are created from heavy, dense steels causing a lack of thermal performance and temperature regulation. Aluminium provides strong insulation to limit heat loss and the entry of cold draughts. This enhances the comfortability of your home and reduces the requirement for air-conditioning or heating. Aluminium is not normally known for its fire resistant properties. However, by utilizing an air-rated cement core, the framing can withstand heats well beyond its normal limits.2. Energy efficiency

By enhancing temperature control, you are not required to use things such as air conditioning and heating as often. Furthermore by increasing natural lighting, you are not required to use artificial lighting as often. This greatly increases your energy efficiency and the performance of your home. By utilizing the thermal and lighting benefits of aluminium not only can it create a more comfortable home or building, but it also helps to shave unnecessary dollars off your energy bills.

3. Save Costs

Many people only consider material costs when specifying fire resistant glazing, most do not consider installation costs and transportation costs. Often steel framing is much heavier and more expensive and due to its immense weight, installation and shipping costs will be much higher as more labor, and equipment may be required. Aluminium framing is much lighter and made from much more sustainable materials making it a more cost-effective material. Furthermore, due to its lighter weight and greater flexibility, installation costs will be much lower as less labor, and equipment is required.SMOKE LEAKAGE

As there is no specific Australian design guidance for Smoke Curtains, designers should consult the European Standard EN12101-1:2005 – Smoke and heat control systems – Part 1: Specification for smoke barriers. This standard provides everything from performance requirements to evaluation of conformity and is a required starting point for all designers using smoke curtains. EN12101-1 also specifies the maximum acceptable amount of smoke leakage at the edge of a smoke curtain to ensure that any opening allows only minimal amounts of smoke to pass through. Whilst the designer can specify to minimise gaps down to 0mm, maximum permissible gaps between a wall and smoke curtains are based on the height of the curtain and can be as follows:

6. Virtually No Maintenance

Aluminium has many benefits that other materials do not. These include:- Naturally corrosion resistant

- Resistant to rusting

- Resistant to weathering under a range of harsh environmental conditions

- Does not swell

- Does not crack

- Does not split

- Does not warp over time