Transforming Fire Protection Design with SOLIDWORKS at Greene Fire

Since its founding, Greene Fire has been at the forefront of fire protection innovation, offering industry-leading solutions to ensure safety and compliance in diverse architectural applications. With a steadfast commitment to quality and innovation, Greene Fire has become a trusted partner in developing bespoke fire protection systems for residential and commercial projects. Recognising the need to enhance its design capabilities, Greene Fire has adopted the SOLIDWORKS platform, revolutionising its design and development processes.

Greene Fire recognised that design in the manufacturing industry is evolving rapidly, with increasing demands for precision, speed, and sustainability. Meeting these challenges requires advanced tools capable of streamlining design processes while maintaining rigorous safety and regulatory standards.

Greene Fire faced these industry-wide challenges head-on by integrating SOLIDWORKS into its operations. The platform has provided a comprehensive solution to accelerate project timelines, improve design accuracy, and deliver unparalleled safety and performance in its products.

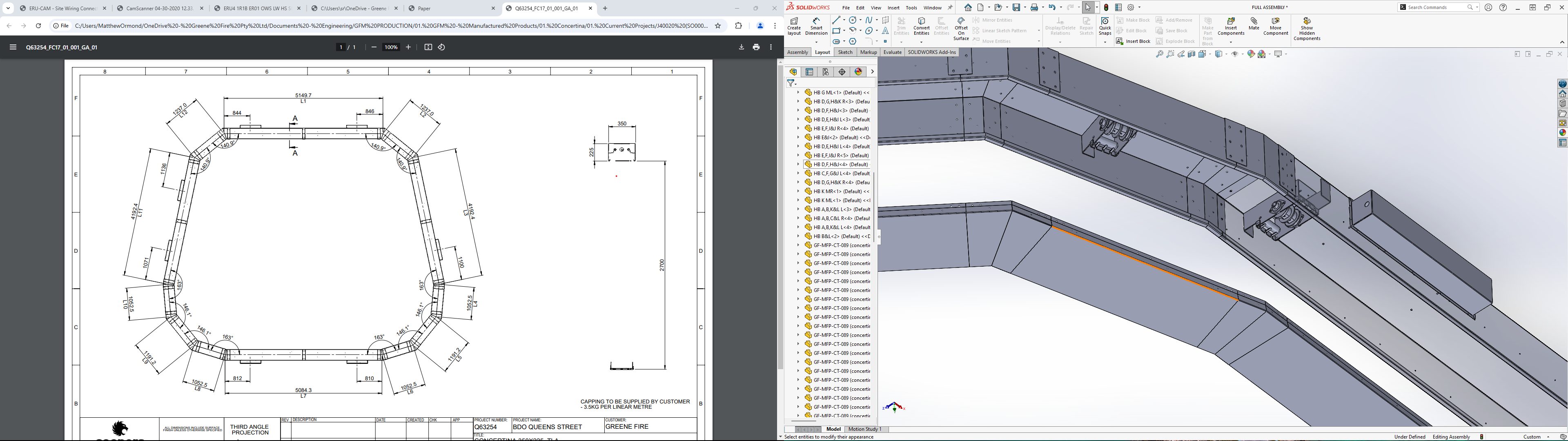

One of the most significant benefits of adopting SOLIDWORKS is the drastic reduction in design timelines. Previously, developing complex fire protection systems, particularly those customised for unique architectural needs, could take several weeks. These designs often relied on collaboration with experts from multiple countries, adding complexity to the process. With SOLIDWORKS, Greene Fire has successfully cut its design cycles by 50%. This acceleration allows the team to finalise intricate projects in a fraction of the time, meeting tight deadlines and responding to client demands almost immediately.

In addition to improving speed, SOLIDWORKS has revolutionised how different departments within Greene Fire collaborate. The software’s seamless integration ensures that every stage of a project, from initial design and 3D modelling to manufacturing - is aligned. This integration eliminates common communication bottlenecks that can arise when transitioning between departments, creating a streamlined workflow that fosters teamwork. Design teams, project managers, and engineers can now work in unison, reducing errors and ensuring that projects are delivered on time and within budget. This cohesive approach not only improves operational efficiency but also enhances the overall quality and reliability of the final product.

With sustainability being a core value at Greene Fire, SOLIDWORKS plays a pivotal role in supporting the company’s environmental goals. The software’s advanced tools for material optimisation enable the team to reduce waste without compromising product integrity. By carefully analysing material requirements and minimising excess, Greene Fire ensures that its operations align with sustainable practices.

Another standout feature of SOLIDWORKS is its capability to reuse and adapt previous designs for new projects. This functionality significantly reduces the time and resources required for product development. Rather than starting from scratch, Greene Fire can leverage proven designs, customising them to meet specific client requirements. This method ensures consistency and reliability while accelerating innovation. The ability to build upon a strong foundation of past work allows the team to focus on refining and enhancing their solutions, driving continuous improvement across all projects.

Overall, SOLIDWORKS has been instrumental in Greene Fire’s ability to maintain its leadership in the fire protection industry. By enabling faster design cycles, fostering seamless collaboration, optimising material usage, and accelerating innovation, the software has empowered the company to deliver superior results while staying true to its values of quality, sustainability, and customer satisfaction.

The Research and Development (R&D) team at Greene Fire has particularly benefited from SOLIDWORKS’ capabilities. The ability to conduct comprehensive designs has accelerated the team’s ability to innovate. Greene Fire’s R&D efforts are now leading the industry in developing compliant solutions.

With SOLIDWORKS at the core of its operations, Greene Fire is well-positioned to lead the fire protection industry into the future. By embracing cutting-edge technology, Greene Fire not only meets the demands of today’s construction challenges but also anticipates the needs of tomorrow.

Greene Fire recognised that design in the manufacturing industry is evolving rapidly, with increasing demands for precision, speed, and sustainability. Meeting these challenges requires advanced tools capable of streamlining design processes while maintaining rigorous safety and regulatory standards.

Greene Fire faced these industry-wide challenges head-on by integrating SOLIDWORKS into its operations. The platform has provided a comprehensive solution to accelerate project timelines, improve design accuracy, and deliver unparalleled safety and performance in its products.

Leveraging SOLIDWORKS for Superior Results

Greene Fire’s integration of SOLIDWORKS into its design and manufacturing operations has been transformative, enabling the company to achieve remarkable improvements in efficiency, collaboration, and sustainability. The software has become a cornerstone of Greene Fire’s commitment to delivering innovative, high-quality fire protection solutions tailored to the unique requirements of its clients.One of the most significant benefits of adopting SOLIDWORKS is the drastic reduction in design timelines. Previously, developing complex fire protection systems, particularly those customised for unique architectural needs, could take several weeks. These designs often relied on collaboration with experts from multiple countries, adding complexity to the process. With SOLIDWORKS, Greene Fire has successfully cut its design cycles by 50%. This acceleration allows the team to finalise intricate projects in a fraction of the time, meeting tight deadlines and responding to client demands almost immediately.

In addition to improving speed, SOLIDWORKS has revolutionised how different departments within Greene Fire collaborate. The software’s seamless integration ensures that every stage of a project, from initial design and 3D modelling to manufacturing - is aligned. This integration eliminates common communication bottlenecks that can arise when transitioning between departments, creating a streamlined workflow that fosters teamwork. Design teams, project managers, and engineers can now work in unison, reducing errors and ensuring that projects are delivered on time and within budget. This cohesive approach not only improves operational efficiency but also enhances the overall quality and reliability of the final product.

With sustainability being a core value at Greene Fire, SOLIDWORKS plays a pivotal role in supporting the company’s environmental goals. The software’s advanced tools for material optimisation enable the team to reduce waste without compromising product integrity. By carefully analysing material requirements and minimising excess, Greene Fire ensures that its operations align with sustainable practices.

Another standout feature of SOLIDWORKS is its capability to reuse and adapt previous designs for new projects. This functionality significantly reduces the time and resources required for product development. Rather than starting from scratch, Greene Fire can leverage proven designs, customising them to meet specific client requirements. This method ensures consistency and reliability while accelerating innovation. The ability to build upon a strong foundation of past work allows the team to focus on refining and enhancing their solutions, driving continuous improvement across all projects.

Overall, SOLIDWORKS has been instrumental in Greene Fire’s ability to maintain its leadership in the fire protection industry. By enabling faster design cycles, fostering seamless collaboration, optimising material usage, and accelerating innovation, the software has empowered the company to deliver superior results while staying true to its values of quality, sustainability, and customer satisfaction.

A Testament to Innovation and Excellence

Clinton Greene, the founder of Greene Fire, underscores the transformative impact of SOLIDWORKS: “Our adoption of SOLIDWORKS has fundamentally changed how we approach design and manufacturing. The platform empowers our team to explore innovative ideas and deliver high-quality solutions that meet the demands of modern construction”.The Research and Development (R&D) team at Greene Fire has particularly benefited from SOLIDWORKS’ capabilities. The ability to conduct comprehensive designs has accelerated the team’s ability to innovate. Greene Fire’s R&D efforts are now leading the industry in developing compliant solutions.

With SOLIDWORKS at the core of its operations, Greene Fire is well-positioned to lead the fire protection industry into the future. By embracing cutting-edge technology, Greene Fire not only meets the demands of today’s construction challenges but also anticipates the needs of tomorrow.